Performance Textiles Can Be Beautiful

At HwaFune, we believe technical fabrics should not only perform—but also look and feel exceptional. Through professional dyeing and textile printing, we help brands achieve vibrant designs on sustainable, high-performance base fabrics.

Dyeing: Enhancing Appearance & PerformanceDye selection is critically dependent on material type and performance requirements. Key considerations include lightfastness, wash and crocking resistance, and process cost. Proper pre-treatment is essential to ensure dye penetration and long-term color durability. You can choose from: |

|

|

Yarn-dyed fabric refers to textiles woven from pre-dyed yarns, allowing precise color placement and pattern definition at the structural level. This method differs from piece dyeing, where color is applied after the fabric is woven. Yarn-dyed constructions are commonly used for patterns such as gingham checks, dobby weaves, and some plaids, offering enhanced colorfastness, visual depth, and design clarity. W-4549-A06

|

|

Tie-dyed fabric is a resist-dyeing technique that produces a broad range of patterns, from recognizable motifs such as spirals, diamonds, and marble effects to more complex, artistic surface designs. It offers visual unpredictability and unique aesthetics, often used in conceptual or limited-edition textile applications. W-4670-P253A06

|

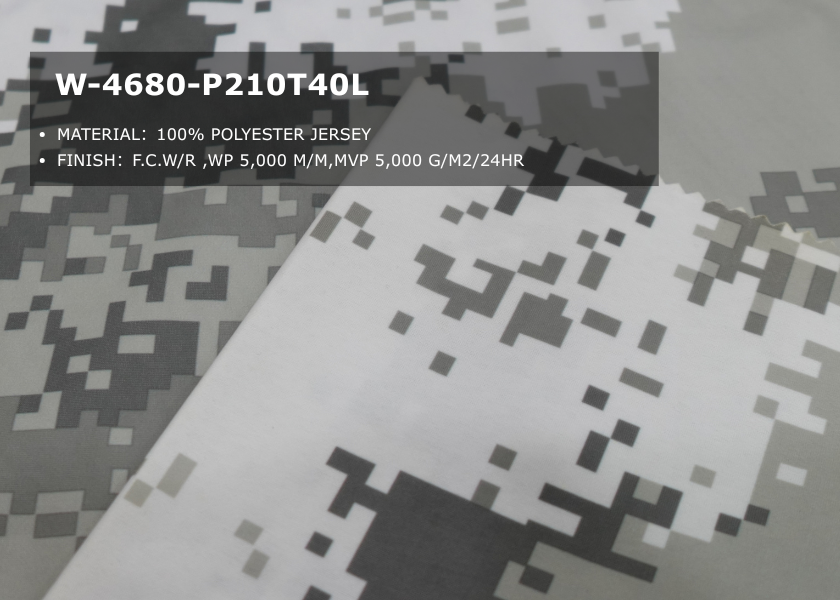

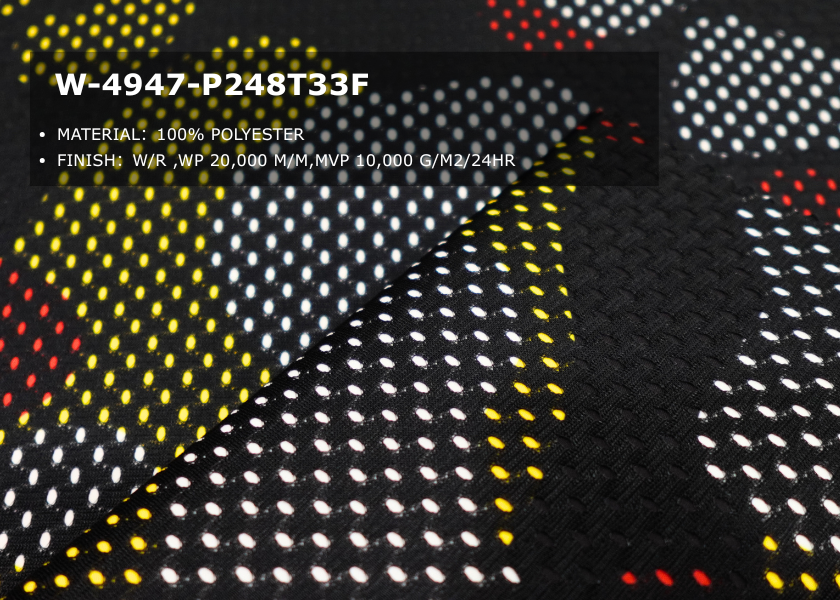

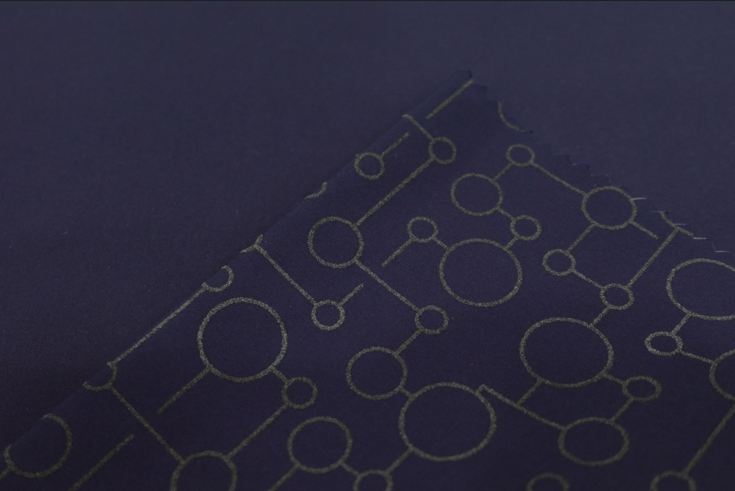

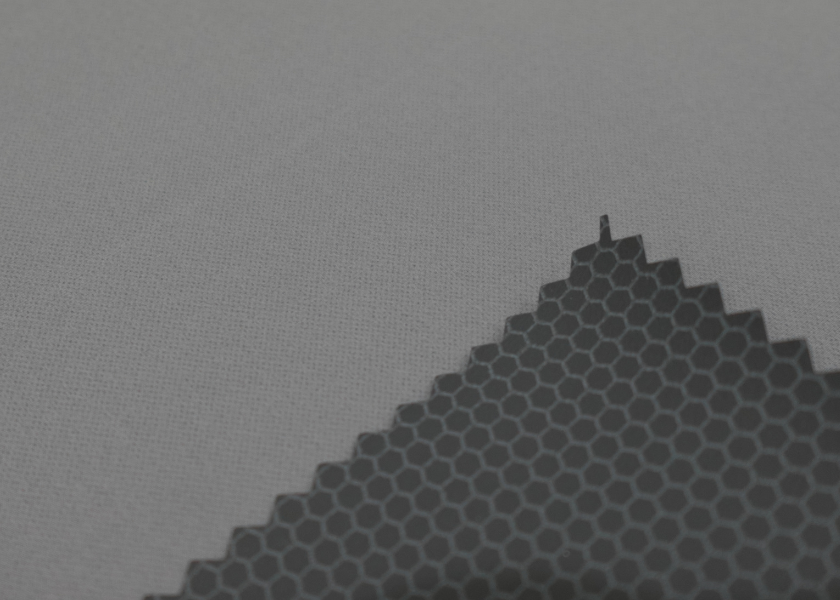

PrintingPrinting is a surface treatment process applied to textile fabrics using pigments, dyes, or other compounds to create defined visual patterns. It enhances both the aesthetic and functional value of printed fabrics used in fashion, activewear, and outdoor applications.

The four primary methods of fabric printing include:

– Block printing

– Roller printing

– Screen printing

– Heat transfer printing

In all methods, color is delivered via a thickened medium, followed by heat or steam fixation and washing to remove unfixed materials. Proper process control ensures pattern clarity, colorfastness, and compatibility with high-performance fabrics.

|

|

Hwa Fune offers over 5,000 fabric options with diverse materials, structures, deniers, and weaves. Choose from eco-friendly textiles and custom printed designs—combining performance, aesthetic versatility, and sustainability.👉 Contact Us Now

Information source: https://www.britannica.com/topic/textile/Printing

Performance Textiles Can Be Beautiful

At HwaFune, we believe technical fabrics should not only perform—but also look and feel exceptional. Through professional dyeing and textile printing, we help brands achieve vibrant designs on sustainable, high-performance base fabrics.

Dyeing: Enhancing Appearance & PerformanceDye selection is critically dependent on material type and performance requirements. Key considerations include lightfastness, wash and crocking resistance, and process cost. Proper pre-treatment is essential to ensure dye penetration and long-term color durability. You can choose from: |

|

|

Yarn-dyed fabric refers to textiles woven from pre-dyed yarns, allowing precise color placement and pattern definition at the structural level. This method differs from piece dyeing, where color is applied after the fabric is woven. Yarn-dyed constructions are commonly used for patterns such as gingham checks, dobby weaves, and some plaids, offering enhanced colorfastness, visual depth, and design clarity. W-4549-A06

|

|

Tie-dyed fabric is a resist-dyeing technique that produces a broad range of patterns, from recognizable motifs such as spirals, diamonds, and marble effects to more complex, artistic surface designs. It offers visual unpredictability and unique aesthetics, often used in conceptual or limited-edition textile applications. W-4670-P253A06

|

PrintingPrinting is a surface treatment process applied to textile fabrics using pigments, dyes, or other compounds to create defined visual patterns. It enhances both the aesthetic and functional value of printed fabrics used in fashion, activewear, and outdoor applications.

The four primary methods of fabric printing include:

– Block printing

– Roller printing

– Screen printing

– Heat transfer printing

In all methods, color is delivered via a thickened medium, followed by heat or steam fixation and washing to remove unfixed materials. Proper process control ensures pattern clarity, colorfastness, and compatibility with high-performance fabrics.

|

|

Hwa Fune offers over 5,000 fabric options with diverse materials, structures, deniers, and weaves. Choose from eco-friendly textiles and custom printed designs—combining performance, aesthetic versatility, and sustainability.👉 Contact Us Now

Information source: https://www.britannica.com/topic/textile/Printing